The Weather Forecast

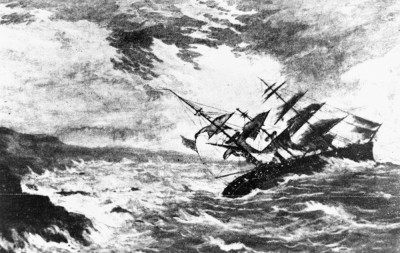

We are having to get used to the frequency and ferocity of storms. We have currently experienced more than seven storms this winter already. With this information in mind, I was very interested in an article about a shipwreck off Porth Alerth near Moelfre on Anglesey that was instrumental in the creation of the shipping forecast. As often happens, tragedy leads to a catalyst for change.

In British weather history, the Royal Charter Storm of 1859 was a devastating tempest off the west coast of Britain which played a pivotal role in the founding of the shipping forecast and has had an enduring impact on weather forecasting in the UK and beyond.